1、summary

Our factory specializes in producing thermocouples, thermal resistances and compensation wires, which have a history of more than ten years. The function of compensation wires is to transmit temperature measurement signals from the site to the centralized control room or extend thermocouples to places with constant temperature. The advantage of using compensation wire is that it can improve the mechanical and physical characteristics of the thermoelectric circuit, increase the flexibility of some circuits, and adjust the resistance value of the circuit and shield external interference.

2、Structure and type

Compensation conductor is generally composed of wire core (single strand or multi strand soft type), insulation layer and sheath; If electromagnetic interference is required, a shielding layer woven with tinned copper wire and galvanized copper wire shall be added to the outer layer.

Due to the different materials of the insulation layer, the compensation conductor has different temperatures, which can be divided into ordinary, heat-resistant and high-temperature resistant grades. The ordinary grade uses PVC insulation layer, which is characterized by resistance to harmful gas corrosion and solvent, and moisture; The heat-resistant grade adopts alkali free glass fiber and is coated with silicone organic paint, which has the characteristics of non combustion, high temperature resistance, good electrical insulation, high mechanical strength and good chemical stability; High temperature resistant grade adopts tetrafluoroethylene insulation layer, which has the characteristics of acid and alkali resistance, oil resistance, flame retardancy, non water absorption, and good insulation performance. According to the compensation principle, it can be divided into compensation type (C) and extension type (X). The extension type uses the same alloy as the thermoelectric electrode used, and is used for low metal thermocouples; The compensation type adopts an alloy different from the thermoelectric electrode used, which is used for precious metal thermocouples and some non-standard thermocouples.

3、Basic parameters

| Thermocouple type | Compensating conductor type | Color code | Tolerance range℃ | Reciprocating resistance valueΩ | temperature range℃ | Ambient temperature and humidity | insulation resistance | ||||

| just | negative | Normal | Precision grade | Normal | Heat resistance class | High temperature resistance | |||||

| Nickel complex constantan(E) | Nickel complex-Constantan(EX) | red | Brown | ±2.5 | ±1.5 | 1.25 | -40~80 | -40~200 | -40~275 | 15~35℃ ≤75% | ≥5 MΩ/10m |

| Iron constantan(J) | iron-Constantan(JX) | " | purple | " | " | 0.648 | |||||

| Nickel complex nickel silicon(K) | Nickel complex-Nickel silicon(KX) | " | black | " | " | " | |||||

| copper-Constantan(KC) | " | blue | ±1.0 | ±0.5 | " | ||||||

| Copper constantan(T) | copper-Constantan(TX) | " | " | " | " | " | |||||

| Tungsten rhenium5-Tungsten rhenium26 | copper-Copper nickel(WC5/26) | " | white | ||||||||

| Platinum and rhodium10-platinum(S) | copper-Copper nickel(SG) | " | green | ±5.0 | ±3.0 | " | |||||

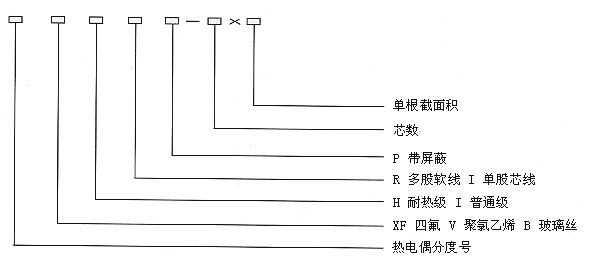

4、Model naming method

|

example:KXXFGIP2×1.5mm2

It indicates that the graduation number is K, the extended compensation wire, the tetrafluoroethylene insulation layer, the single core ordinary grade, the shielding layer, two core wires, and the single sectional area is 1.5mm2

5、Maximum outer diameter, insulating layer and sheath material and thickness of compensating conductor

Insulation sheath Material (temperature) | Nominal section mm2 | Wire core(mm) | Insulation thickness(mm) | Sheath thickness(mm) | Maximum outside diameter(mm) | |||||

| Single share | Multiple shares | Single share | Multiple shares | |||||||

Polyfluoroethylene(275℃) polyvinyl chloride(100℃) | 0.5 | 0.8 | 7×0.3 |

| 0.8 | 3.7×5.7 | 3.8×5.8 | |||

| 1.0 | 1.13 | 7×0.43 |

| 1.0 | 5.0×7.7 | 5.1×8.0 | ||||

| 1.5 | 1.37 | 7×0.52 |

| 1.0 | 5.2×8.3 | 5.4×8.7 | ||||

| 2.5 | 1.76 | 19×0.41 |

| 1.0 | 5.7×9.2 | 5.9×9.7 | ||||

Alkali free glass fiber weaving External silicon mechanical paint (200℃) | 0.5 | 0.8 | 7×0.3 |

| 0.3 | 2.6×4.6 | 2.7×4.8 | |||

| 1.0 | 1.13 | 7×0.43 |

| 0.3 | 3.0×5.3 | 3.1×5.6 | ||||

| 1.5 | 1.37 | 7×0.52 |

| 0.3 | 3.2×5.8 | 3.4×6.2 | ||||

| 2.5 | 1.76 | 19×0.41 |

| 0.3 | 3.6×6.7 | 4.0×7.3 | ||||

6、Ordering Instructions

1、Please specify the model of compensation wire and the graduation number of the thermocouple.

2、Outer diameter, number of layers, order quantity, delivery date, etc. of compensation conductor.

QQ:

手机:

电话:+86-577-61315899

邮箱:londer@londer.com

地址:No. E-1, West Industrial Zone, Hongqiao Town, Yueqing City, Zhejiang Province

如果您有任何问题,请跟我们联系!

联系我们